The Dodo Blog

Looking for a new creative challenge?

I’ve got you covered!

Until Sunday, October 5th, get the class STAR ANISE SEED POD for only 99€. That’s 30€ off the regular price!

This is an exclusive offer for newsletter subscribers. So, if you’re on the email list, please check your inbox for this special...

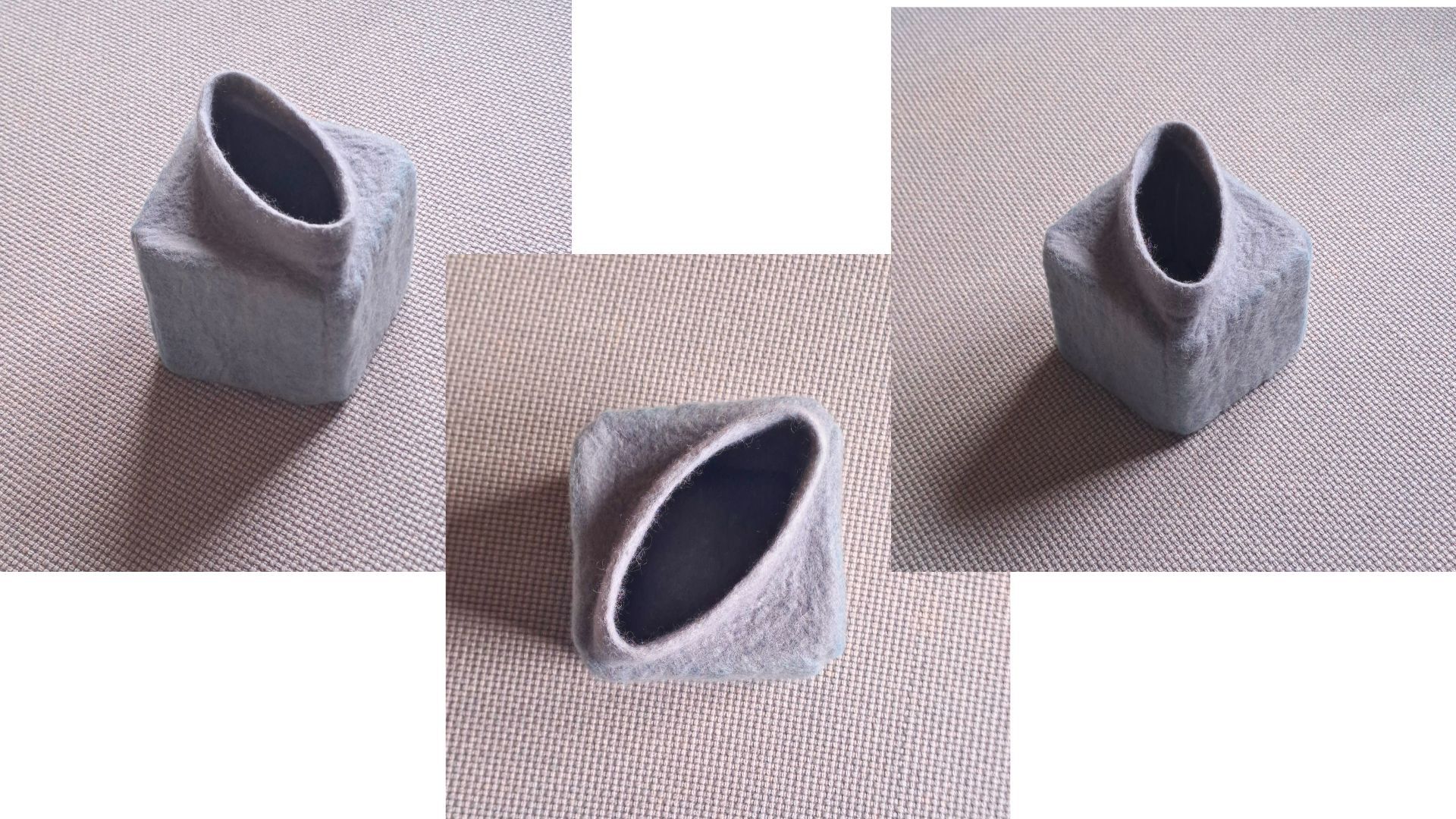

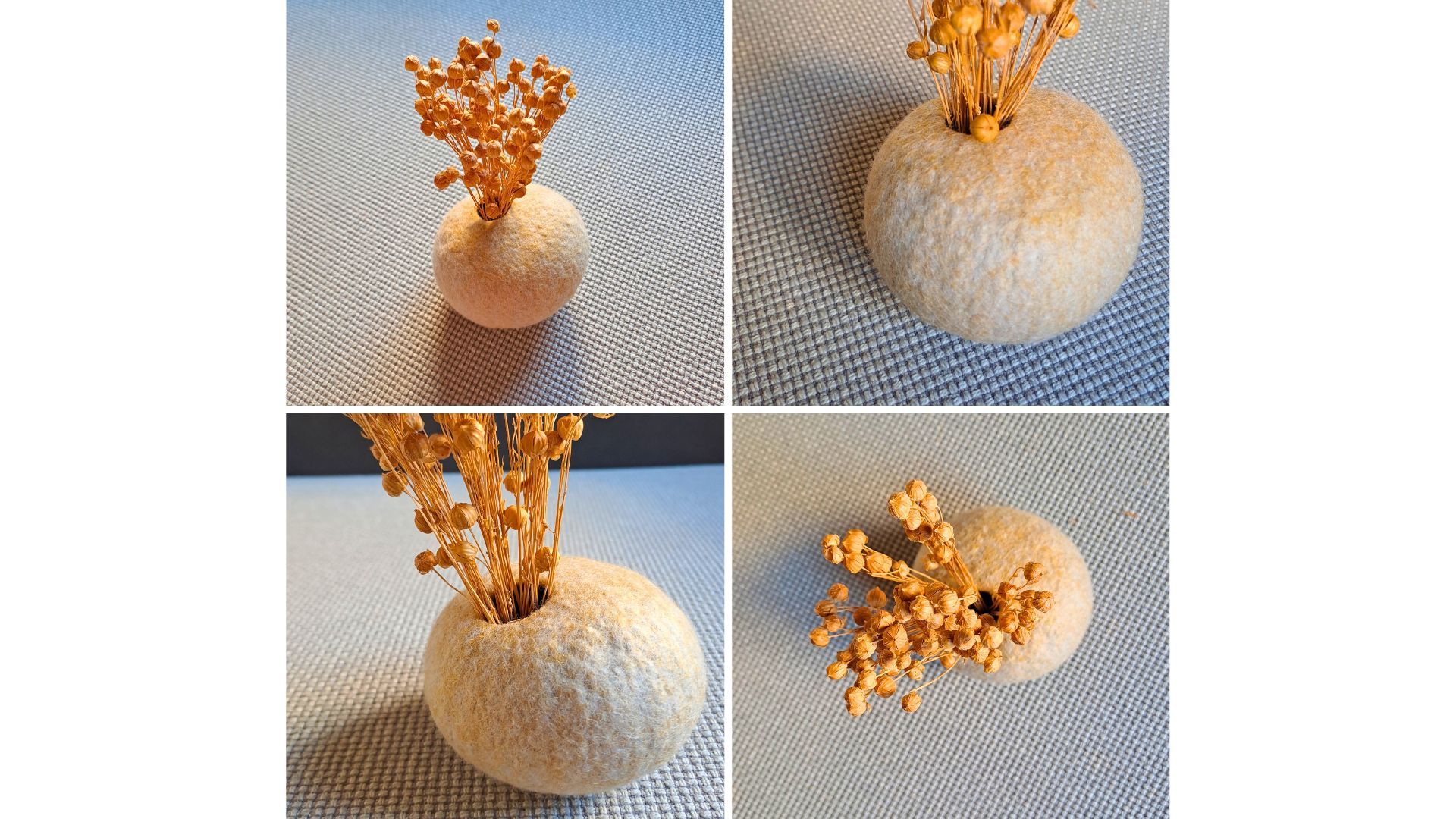

We’ve started a little tradition in The Dodo Hub: once a month we hop online and felt together. Lately, the challenge has been about the circle. We grab a round resist, and experiment with the techniques from the program.

You can felt anything you’d like to try, as long as you start with that circl...

Today, I want to talk to you about something that makes felt makers a little bit nervous: the S word. SAMPLES!

While I know most of us would do anything to avoid making samples before we felt a piece, I’m – once again – going to try to persuade you to make them.

Now, when we talk about making sa...

If you’ve been waiting for the registration to THE DODO HUB to open, I’ve got good news. You can now sign up here.

WHO IS THE PROGRAM FOR?

You’ve been a felt maker for some years now, but …

- you feel like you’ve reached a plateau, and you don’t know how to develop your work further;

- you wan...

After experimenting with wet felting for some time, learning the basics and maybe even felting some pieces on a resist, you may feel you’d like your felt to become more professional and well finished. Yet, you may also not know what to do to get to that next level of quality you’d like to achieve.

...I frequently get emails from felt makers asking me if they can purchase only the patterns for my baby booties. When I taught how to make slippers, I was often asked if I’d sell only the patterns for the slippers.

I opted for never offering the resist patterns, the reason being that I’m for teaching...

About two years ago, I taught a class called RESISTS MADE EASY – A PROVEN SYSTEM TO DESIGN RESISTS FOR WET FELTING.

It covered how to make resists for shoes, clothes, hats, bags, gloves and vessels in all sorts of shapes.

It was well received and fun to teach. But, next, I started focusing more on...

So you had a look at the program, and now you’re thinking “Yes, one technique a month. But what do we really felt inside THE DODO HUB?”

I get that it may not be totally clear to you, so let me help you with that.

First, above there's a short video of some of the beautiful pieces made by the partic...

If you’ve been waiting to enroll in THE DODO HUB, I’ve got good news! The registration is open as of now.

Are you new to the DODO world, and not sure what THE DODO HUB is?

- It’s a comprehensive year-long program designed to take you from the intermediate level to an advanced and independent ...

Are you looking for an original gift for someone who loves wet felting?

Look no further! Now, you can also purchase ANY of these classes as a gift for someone you love.

How does this work?

1. Click the links below to go to each course page.

When I created THE DODO HUB, my year-long program, in 2023, many felt makers said that one year was too long for them. But they were interested in some of the topics covered in the program.

So, to give everyone the chance to participate, I started offering some of the classes separately. You’d get ...

I don’t use stiffeners often. But sometimes they can be useful, especially for sculptural wet felting. The problem with stiffeners is finding one that doesn’t make your work very hard, and still lets your felt look natural.

As in many other aspects of felt making, there are different opinions about...