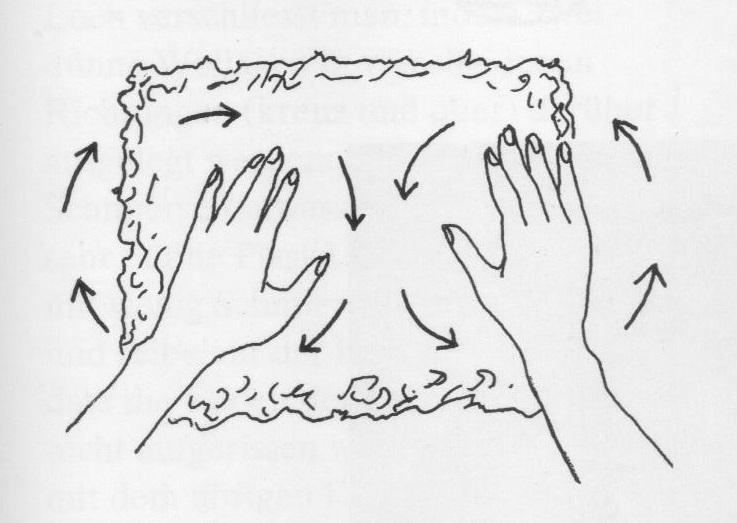

TOSSING/THROWING/TUMBLING

Welcome to the last part of this series on how to apply pressure in wet felting.

This is another one of my favorite methods for fulling. Since I love working with my hands, and prefer avoiding tools, I use the TOSSING/THROWING technique in nuno felting, as well as when I’m making pieces without fabric, but where the wool has been laid very thinly (cobweb felt). This is only done in the last stages of fulling, after I’ve secured the fibers in place through rolling a bit, of course.

This technique doesn’t full the felt as evenly as rolling, but I like it because it causes a quick shrinkage, and gives the felt surface a more textured and wavy look.

I would recommend this method for small or thin pieces. I’ve used this method for all the items below.

Before you do the throwing, make sure you have enough water and soap in your piece, but it shouldn’t be soaked. Start gently, and throw harder as you progress. Do it in the sink or the bath tub, because it ca...